- Surface Jet Pump and Compact Separation Solutions

Tags

Surface Jet Pump and Compact Separation Solutions

We take your production challenges and make them our own, working with you to provide a solution.

Unlocking energy supplies - safely, securely and responsibly - has never been simple. Every oil and gas platform, pipeline or plant, represents years of ingenuity and innovation at a macro and a micro level.

Our passive technology enables oil and gas operators to harvest energy already held within the reservoir and production facilities, with three results: enhanced production, extended economic life of fields, and a reduction in environmental impact.

Our unique, specialized knowledge in the design and application of a range of technologies means that we are able to work through a full project life cycle with you, finding optimization opportunities for production enhancements and efficiencies at many stages.

With decades of experience in improving productivity from oil and gas wells and enhancing production processes, we have successfully implemented over 100 Installations Around the World. The map provides examples of our completed installations of our innovative productivity solutions for most of the oil and gas majors around the world.

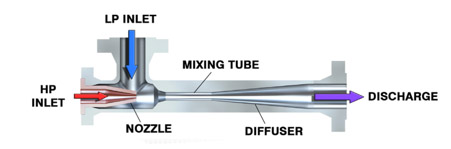

Surface jet pumps use available high-pressure sources as a motive flow; in so doing, they can boost the pressure of a low-pressure fluid.

Bulk or coarse splitting of phases overcoming pressure, space and weight constraints compared to conventional separation process vessels.

Solutions

There are many cases where combining two fluids of different pressures, flow rates, density or viscosity, can restrict flow from the weaker source, if a ‘tee’ section is used.

There are solutions which enable compressors to be replaced with surface jet pumps.

Preventing flaring of LP gas and boosting it to a higher pressure for utilisation has environmental benefits.

Produced solids, such as sand, cause many problems for the oil and gas industry.

Increasing the flowing pressure and/or reducing the back pressure in the production process can enhance production from low-pressure gas or oil wells, thereby prolonging the life of the field and improving total recovery factors.

Multiphase fluids often separate in production pipelines causing the formation of slugs which are detrimental to the operation and design of downstream production systems.

The compact separator can remove dissolved gas in liquid phases, without the need for vacuum separators and pumping systems.

Surface jet pump technology (also known as Ejectors, Eductors, Jet Pumps and Velocity Spools) offers simple solutions to boost the pressure of the liquid phase without the need for a conventional powered booster pump.

Both oil and gas production involves producing a mixture of gas and liquid phases, and the challenge is boosting the pressure of both phases.

Many mature oil and gas fields face production of excessive water cuts, sometimes reaching 90% or above thereby causing bottlenecks in the production process and pipelines.

Increases in gas production or the lowering of the separator pressure can result in overloading for the separator.

Preventing venting gas has major environmental benefits; solutions are available for boosting its pressure to enable its utilisation cost effectively.

The surface jet pump can be used as a cost-effective solution to debottleneck compressors, boosting the suction or bypassing one or more stages to enhance operations.

Increases in gas production or the lowering of the separator pressure can result in overloading for the separator.

Boosting the pressure of low-pressure gas to a higher pressure to meet process requirements or to produce at a lower back pressure can be achieved cost effectively without the need for costly compressors.

Caltec Surface Jet Pumps (SJPs) have been used successfully in many applications for well deliquification purposes.

Caltec Surface Jet Pumps (SJPs) can also be used in-conjunction with artificial lift systems, such as Gas Lift injection.

For more details please Contact Us today.